It can be used for high precision and small amount of lapping processing

Application:

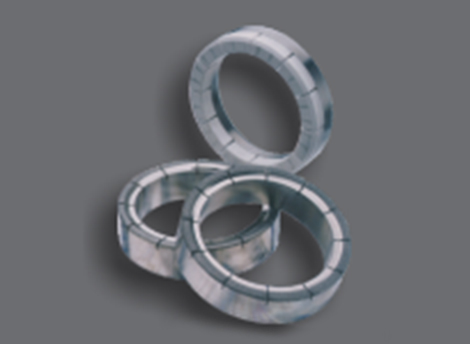

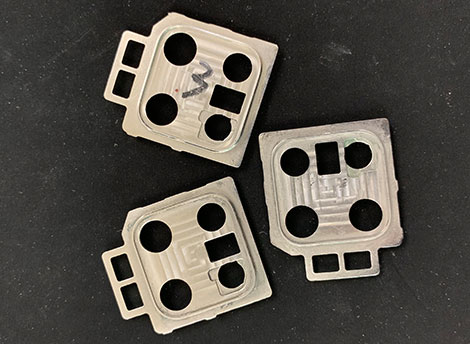

This series products is designed and produced for single surface lapping and polishing stainless steel, mold steel, air pressure, hydraulic pressure, seal pieces all kind of hardware components ect metal and non-metal material.

Machine Principle:

The lapping machine is single-sided precision lapping and polishing machine. The workpiece need to be lapped and polished is placed on the lapping plate. The plate rotates counter-clockwise. The workpiece rotates by friction force, and the pressure is applied on the workpiece by the clump weight. The workpiece and the lapping plate do relative friction motion to achieve the purpose of lapping and polishing the workpiece.

Features:

SMC precision pressure device

Reduce workload, improve production efficiency and reduce production cost.

Automatic fluid charging device

Mechanical or magnetic stirring can prevent the deposition of abrasive particles in the grinding fluid. The grinding particles can be evenly sent to the surface of the grinding plate regularly and quantitatively, so that the grinding fluid can be more fully utilized, reduce waste, save the cost of consumables and meet the requirements of environmental protection

High precision disc repairing machine

This unit is equipped with KX series of precision fix plate machine, the plate can be repaired in a short period of time to be a best flatness +/-0.002mm, besides opening process groove in accordance with the requirements in the mill working face grinding/polishing process, the unit can select application mill cooling systems according to the application requirements, can avoid affecting the grinding/polishing quality due to the high temperature.