It can be used for high precision and small amount of lapping processing

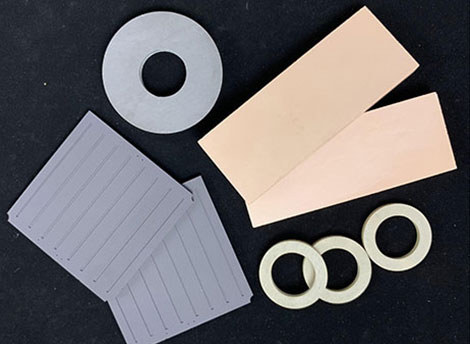

Application: Major in precise lapping valve plate, valve piece, friction plate, rigidity seal ring, air cylinder piston ring, oil pump vane etc precision hardware or metal and non-metal hard material's double side lapping.

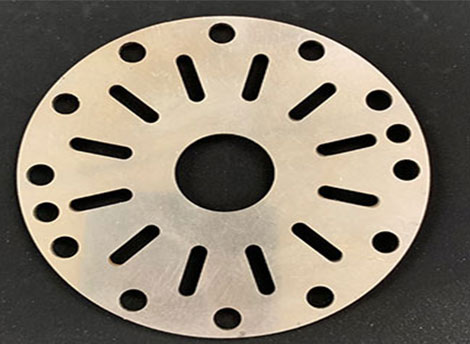

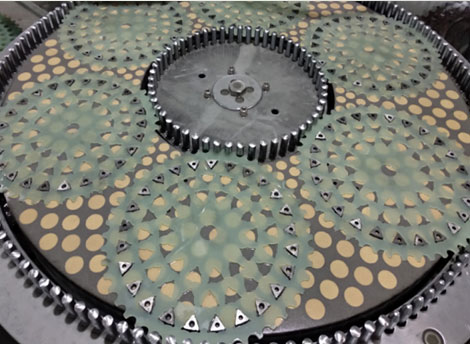

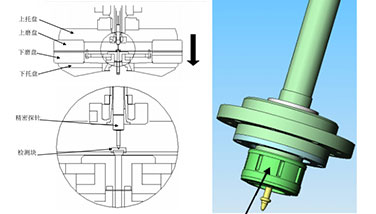

Machine principle: The grinding machine is a double-sided precision grinding and polishing machine. The workpieces need to be grinded and polished are placed on the lower grinding disc. The upper and lower grinding discs rotate relative or in the same direction. The central gear rotate the carrier and make the workpiece orbital revolution or self rotation. Pressure the upper grinding disc through the cylinder, and the workpieces and the grinding disc are uniformly rubbed in relative motion to achieve the grinding and polishing purpose of the workpieces.

Features:

1.Use Swedish “ABB”、PLC program control system, to make sure the stability and safety of machine;

2.Use Japanese “NSK”/ German “FAG” high precise high speed shaft system; Effectively ensure the working accuracy when high speed, high strength lapping;

3.Intelligentialized automatic thickness detection system, the best accuracy of resolution is up to 0.001um. Make sure mass production item thickness size tolerance have stable TTV;

4.Upper plate rocker arm device with matching feeding working table improved the Pick & Place convenience;

5.Upper plate automatic protection device, prevent accident like fall plate caused by unexpected expired and power failure;

6.Use independent inverter motor drive, make the upper plate, lower plate, center wheel and the speed reach the best ratio, and make the loose pully realize clockwise rotation and iversion, and satisfy each machining and fixplate artwork requirement;

7.Use Japanese “SMC” pneumatic element matching stepless mutistage precise pressing control system, suitable for coarse lapping, middle lapping, precise lapping, polish ect artwork requirement;

8.To meet different material machining requirement, develop customize adamas lapping plate with different formula;

9.Precise magnetism and paper tape filtration system.

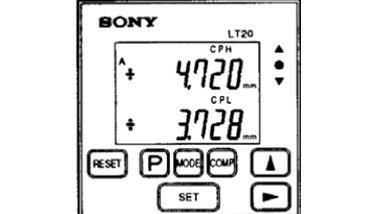

SONY Dimension Control System

Intelligentialized automatic thickness detection system, the best accuracy of resolution is up to 0.001um. Make sure mass production item thickness size tolerance have stable TTV